GKW Restoration Group: Trusted Historic and Masonry Restoration Contractors in Kansas City, MO

A Skilled Team Dedicated to Historic and Modern Building Needs

Preserving History While Restoring Structural Integrity

Masonry and Historic Restoration Services We Offer

• Tuckpointing and new masonry work completed by skilled restoration-focused masonry contractors

• Masonry restoration services that repair aging materials while maintaining historic character

• Building caulking services that manage movement and moisture in critical areas

• Professional sealant services including, joint sealants, sealers, and expert sealant replacement

• Precision caulking installation that supports both waterproofing and preservation goals

Why Choose GKW Restoration Group

We specialize in

Frequently Asked Questions

What restoration and building-envelope services do you self-perform versus subcontract?

a. GKW self-performs the following Division 04 scopes: new masonry, masonry restoration including tuckpointing, façade cleaning, stone and brick replacement, CMU repairs, stone patching, concrete patching and repairs (Div 03), and façade assessments.

b. GKW self-performs the following Division 07 scopes: waterproofing, joint sealants, air/vapor barriers, traffic coatings and firestopping.

c. GKW subcontracts engineering and design work as well as stucco or EIFS work

What experience do you have with historic and landmarked buildings?

We specialize exclusively in commercial and historic masonry restoration and have completed projects on landmarked, registered, and tax-credit–eligible buildings. Our team understands preservation requirements, review processes, and the care required when working with fragile, historic materials. We regularly coordinate with owners, consultants, and reviewing authorities to keep projects compliant and moving forward.

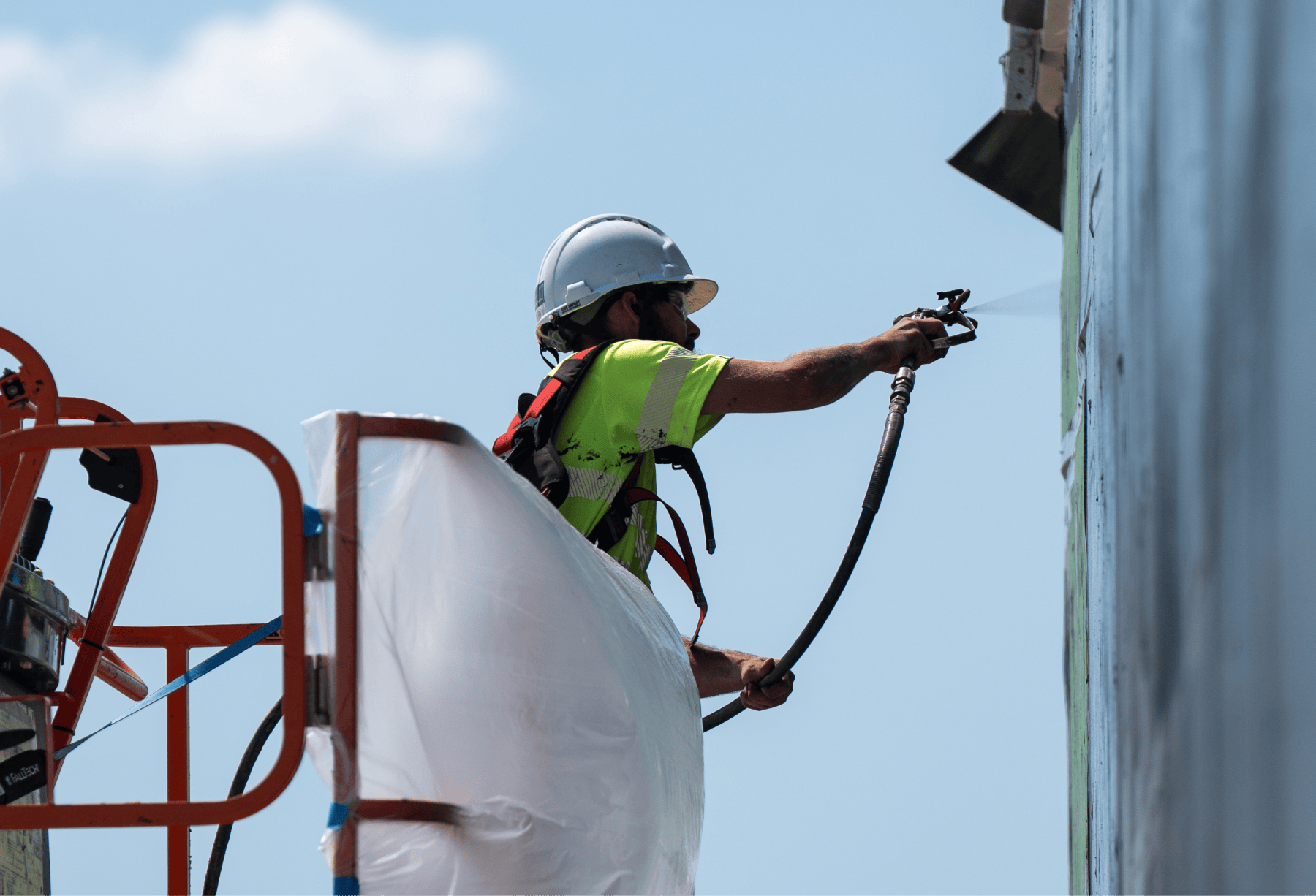

How do you manage access, scaffolding, and façade logistics?

We plan access early and collaboratively. Our team has extensive experience with scaffolding, swing stages, aerial lifts and complex urban access conditions. We coordinate sequencing, safety, and site constraints with the GC to minimize disruptions and maintain steady progress.

What does your safety program look like on active job sites?

Safety is a top priority on every project we perform. We maintain a comprehensive safety program supported by a third-party safety company that manages our monthly, company-wide safety trainings and meetings. These sessions focus on the most common and critical safety issues encountered in the field, ensuring our crews remain informed and prepared.

In addition, the third-party safety firm conducts weekly job-site visits and provides detailed reports identifying potential safety concerns, verifying compliance, and reinforcing best practices. This proactive approach helps ensure a safe work environment for our teams, our partners, and all other trades on site—while maintaining full compliance at all times.

What is GKW’s EMR?

We are proud to say that our EMR for 2026 is 0.72

What geographic areas do you cover?

Our headquarters is in Kansas City, with offices in Manhattan, KS and Denver, CO. Through those offices we cover Missouri, Kansas, Nebraska, Iowa, Colorado, and Wyoming. We also travel to other parts of the country for specific relationships or opportunities.

How many employees does GKW have?

GKW currently has approximately 50-55 employees total from office to field personnel.

How long has GKW been in business?

GKW was founded in 2015 in Kansas City, so we just passed 10 years in business. We expanded to Manhattan in 2019 and Colorado in 2021.

Are you bonded and insured?

Yes, we are fully bonded and insured typically above and beyond anything we are asked to provide for most commercial projects.

What types of clients do you typically work with?

We primarily work with general contractors, property and facilities managers, developers, institutional owners, and public agencies with projects across a wide range of building types.

What project sizes do you typically handle?

Our team routinely supports projects ranging from targeted façade repairs to large-scale, multi-phase restoration and building envelope scopes on new ground-up projects

In terms of dollars, we do projects as small as $5-10k up to $5M+

Do you provide preconstruction or budgeting assistance?

Yes. We frequently assist GCs during preconstruction with scope review, budgeting, constructability input, and sequencing recommendations—particularly on historic and façade-driven projects where early planning is critical.